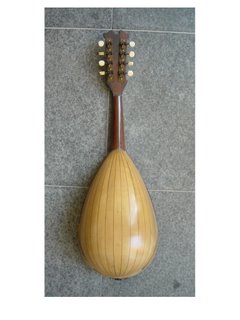

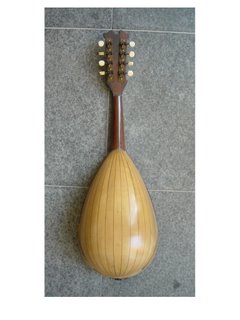

Luigi Dorigo "DeMeglio" model mandolin in

pristine condition. No cracks or reparations of

any kind. The little piece of wood to press the

strings downwards behind the bridge has gone.

Easy to make but I would not recommend it.

The back has been relacquered probably.

It exists of 15 ribs and two closing ribs.

Closed machineheads as was common on the

more expensive models. They do resemble

the DeMeglio tuners a lot.

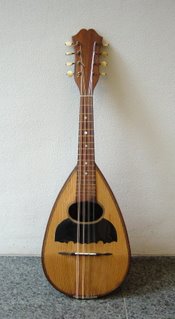

A nice and straight neck, veneered as was

done by most mandolin manufacturers.

The endcap that still has its' original finish.

The snakewood linings. And the typical holes

on each side of this instrument.

The tuners and you are able to study a kind

of "double fret" topnut mounted here.

Besides a nicely ornamented scratchplate the

position markers are strange in a way that they

have drilled holes in the center. Same on the head.

A very well preserved soundboard and scratchplate.

This instrument hasn't been played a lot but the reason

for that simply is not the sound which is even better

than the DeMeglio mandolins I had.

The holes in the center of the position markers

can be studied here. Just click on the picture.

This is the DeMeglio Headform or was it the other

way round? DeMeglio copied Luigi Dorigo?

At the bottom the two holes in the soundboard still

can be seen. A mandolin with a nice playing action

No damages on the soundboard itself which is

remarkable for a 123 year old instrument.

LUIGI EMBERGHER.

A very well preserved mandolin type Orchestra II.

Somewhat later built but still with the same care!

Year of production: 1947.

Of course interesting to see how Embergher himself made the strutting

of his mandolins. Recognizable are the wooden strips that are glued

from the inside and are ment to keep the ribs together. But also the

two ribs glued on each side of the sound hole that most likely acts

to prevent the deformation in this area that is prone to it because of

the string tension there. With many thanks to Dave Hynds who

supplied this picture to me. What also can be determined is that

the fretboard first has to be sawed through the fretslot where

the neck meets the bowl. Only in that manner the soundboard

can be removed safely. As opposed to a lot of other mandolins

the glue strip to fetch the soundboard to the bowl are showing

no interruptions.

This mandolin type Orchestra II has 28 ribs out

of maple. It is in a near new condition apart

from some strange scratches between bridge

and stringguard.

Beautiful figured woods used for the ribs.

The asymmetrical scratchplate is there as is the

inlay in the headstock. Stamped on the back.

The tuners often differed from each other within time.

Most of the time the sort of plastic knobs are riveted

on the axes.

Still gracefullly with a small damage on the headstock

high left but I will cure that before the selling.

Tuners that still work well.

Though these pictures can be misleading as for the

camera doesn't keep longer lines straight this neck

is in good shape.

Extended fingerboard as is present on all Orchestra models.

The original bridge and endcap. Some scratches

on this furthermore like new instrument.

Luigi Embergher Orchestra I model.

A bit of an odd looking Luigi Emberger as on most models

that typical asymmetrical scratchplate can be found.

This model definately is an orchestra model as Embergher

only started to produce student instruments on request

after a while. This instrument can be dated 1902.

The back still is in a gorgeous condition but that has

everything to do with the way he veneered the inside

of his backs so chances are small that ribs will open.

Information can be found on various sites that claimed Embergher

started in the Via delle Carrozze 19 in 1903. That explains this

fairly plain label though it is widely known that Embergher

used a variety of labels. This instrument is dated on

this label 1902!

By clicking on this picture you are able to determine

that in the lower middle of this label the year has been

handwritten. The veneering of his mandolins can

be studied here as well.

The nice headshape with its new tuners and still

the broken nut that I've replaced with an ivory one.

Curious of course is that this engraving has been done without the h

but original anyway. Check Willam Petits' site regarding this

particular model. The engraving on the back of that headstock

appears to be exactly the same.

Though not clearly visible this instrument has a nice playing action

the Embergher mandolins are known for.

A shot of the stringholder and the endcap. It has to be

said once again: Soundwise these instruments are hardly beatable

not only volumewise but they also have a great tone

and nice basses as well. The odd key under the stringhooks

has a purpose as well: To keep the metal stringguard in

place. However that has disappeared regretfully.

EMBERGHER MANDOLA

Presented here is a mandola out of the Orchestra Series 1.

This particular instrument was made in 1925 and has all original

parts though it needs some restaurationwork as the harmonic

bars came off and as a result the soundboard deformed.

In fact a bit strange as some ribs loosened while

Embergher mandolins are known for their solid

bowl construction. But in nearly 100 years a lot

can happen to an instrument.

The head form from the Orchestra modells differs from

that of the student models although even these instruments

are of a high quality. Original tuners with ebony knobs.

The head has been stamped on the front and you can study

it quite close by clicking on this picture.

Somebody tried to reglue some ribs but this

can be done better once the soundboard has been removed.

The tuners that only needed to be oiled to work properly again.

These tuners also stand for quality as do the woods choosed.

The black knobs (on this instrument) are riveted.

The Mandola with its' fingerboard removed. The first thing

to do was to make this removal as only then the soundboard

can be removed. This can be done with fairly simple tools

as a sharp and thin cutting knife and a Hair dryer.

I start at the top (first fret) and while masking of the wood

of the head, I''ll heat the fingerboard only on the first 2 or

3 frets.That's enough to work in a razor blade knife (The

ones in the older shaving equipments) Than follows the

slightly thicker blade so I can work in some water with

an injection needle. After some time (hours!)repeat the last

procedure and try to work the knife towards the soundbox

carefully checking both sides of the fingerboard to keep

things straight. The other end of the fretboard should be kept

wet by winding a wet towel around it. Leave it there for

at least 8 hours. When you have worked your way towards the

soundbox the extended fingerboard allready should be loose.

The soundboard removed without any damage and that

is something you allways hope for. At first I tried it with

in water drenched cottonwool and place it on the glued

parts to be removed. The rest sometimes with a heated

knife, a hair dryer and even a flatiron for the part nearest

to the inner heel. No cracks anywhere!

A nice shot of the label then is possible.

The inner bracing loosened and most likely after that the

soundboard deformed as a result of string tension.

A possible solution could be to remove the braces and

bow the soundboard back as too much pressure is needed

to glue them back in place now.

FRATELLI ESPOSITO MANDOLIN

This family is claimed to be one of the more important families

that built mandolines at the turn of the century.

This instrument has a good balance and even response of all stringpairs.

A nice full and brilliant tone comes out of this mandoline.

The back of the Esposito mandoline shows clearly that

maple ribs have been used for this bowlback.

The label of the Fratelli Esposito mandolin

stating they are pupils of the Vinaccia family.

It also dates this instrument on 1897.

The back of the Esposito mandoline shows clearly that

The back of the Esposito mandoline shows clearly that